3D Printing Photo Report

From titanium powder to a hip socket

Additive Manufacturing, AM in brief, is fascinating: As if by magic, complex workpieces grow in 3D printers: layer by layer by layer ... – without human intervention, as it may seem at first glance. But the technology is demanding and requires a lot of manual work with a sure touch, as a visit to the expert team at the Swiss m4m Center in Bettlach shows.

The Technology Transfer Center in Bettlach near Solothurn does not work for profit, but promotes 3D printing in the medical technology industry – with further training and innovative projects. The target group are Swiss SMEs that lack experience and equipment for this promising technology.

Opened in September 2020, the “Swiss m4m Center” has been certified since mid-April according to the ISO 13485:2016 standard for medical technology products. This step now allows professionals to manufacture real products with the production line they had previously installed and tested.

A virtual visit to the Swiss m4m Center

AM-TTC Alliance

More information: www.swissm4m.ch and www.am-ttc.ch

|

Dr. Pierangelo Gröning Nicolas Bouduban |

Communication

Phone +41 58 765 44 54

redaktion@empa.ch

Homepage of the Swiss m4m Center in Bettlach

Transfer center for medtech certified: Green light for "Swiss m4m Center";

Media release April 2021

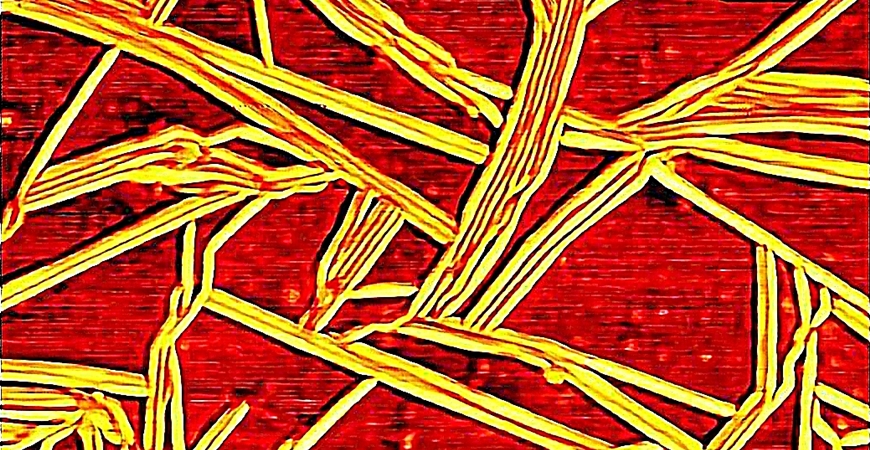

Molecular diagnosis

Detecting Alzheimer's in blood

Empa researcher Peter Nirmalraj wants to capture images of Alzheimer's peptides with unprecedented precision. This could allow new insights into the molecular pathogenesis of the neurodegenerative disease – and perhaps open the way to new therapies.

>>>>

Better fibers

A jacket from a jacket from a jacket ...

Manufacture, wear, wash, incinerate: This typical life cycle of garments, which pollutes the environment, is to be changed in the future – towards principles of circular economy with recycling at its core. Using an outdoor jacket made from PET bottles and recycled materials, Empa researchers have investigated whether the product actually delivers what the idea promises.

>>>>

Interview

"Recycling is not always sustainable"

>>>>